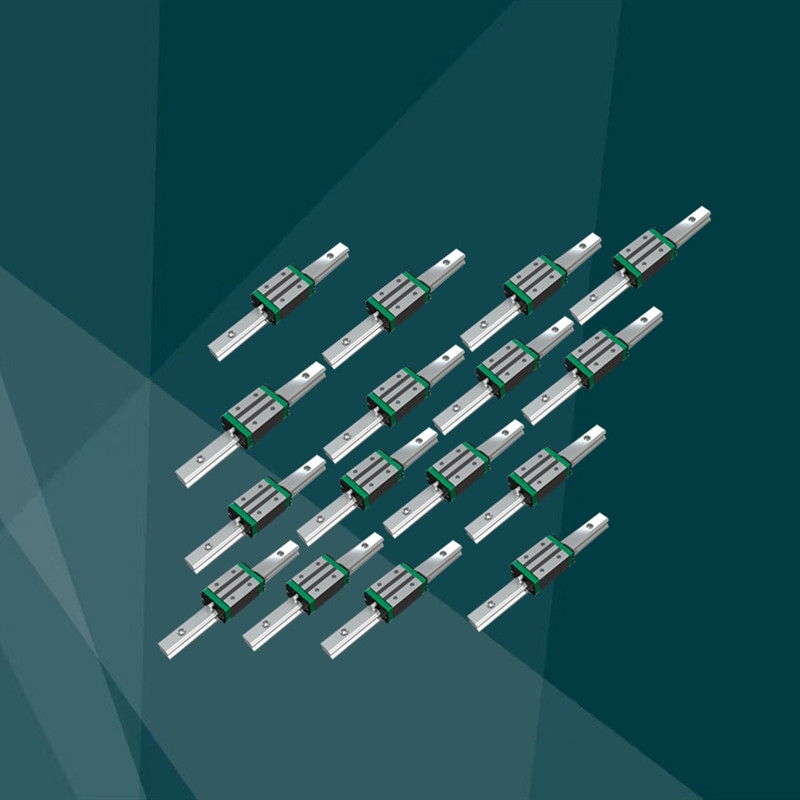

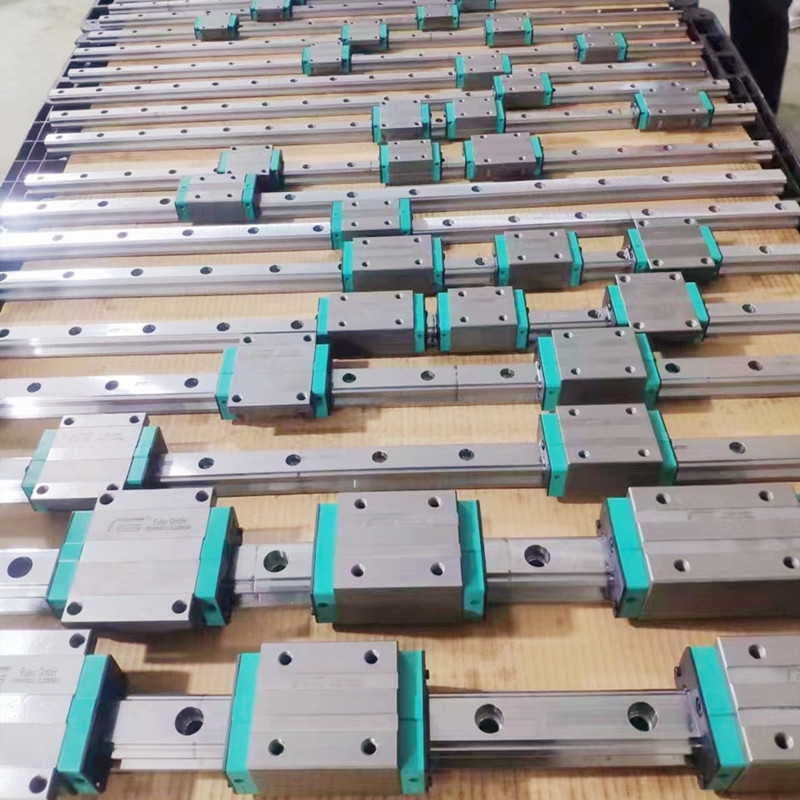

Precision linear guide rail

Linear slider, also known as track, slide rail, linear guide rail, or linear slide rail, can be divided into three types: roller linear guide rail, cylindrical linear guide rail, and ball linear guide rail. Linear guides are used in high-precision or high-speed linear reciprocating motion scenarios, and can withstand a certain amount of torque, enabling high-precision linear motion under high loads. In mainland China, it is called linear guide rail, while in Taiwan it is generally called linear guide rail. The function of linear guide motion is to support and guide moving parts to perform reciprocating linear motion in a given direction. According to the friction properties, linear motion guides can be divided into sliding friction guides, rolling friction guides, elastic friction guides, fluid friction guides, and other types. Linear bearings are mainly used in automation machinery, such as machine tools, bending machines, laser welding machines, etc. imported from Germany. Of course, linear bearings and linear shafts are used in conjunction. Linear guides are mainly used in mechanical structures with high precision requirements. There is no intermediate medium between the moving and fixed components of linear guides, but rolling steel balls are used.

Application areas:

1. Linear guides are mainly used in automation machinery, such as machine tools imported from Germany, bending machines, laser welding machines, etc. Of course, linear guides and linear axes are used in conjunction.

2. Linear guides are mainly used in mechanical structures with high precision requirements. There is no intermediate medium between the moving and fixed components of linear guides, but rolling steel balls are used. Because rolling steel balls are suitable for high-speed motion, have low friction coefficients, and high sensitivity, they meet the working requirements of moving parts such as tool holders and drag plates in machine tools. If the force acting on the steel ball is too large, the steel ball will withstand the preload for too long, resulting in an increase in the resistance of the bracket movement.

Usage precautions:

Linear guides are precision components, so a considerable degree of caution is required when using them. Even if high-performance linear guides are used improperly, they cannot achieve the expected performance effect and are prone to damage. So, when using linear guides, the following precautions should be taken:

Prevent rusting

When directly taking the linear guide rail by hand, it is necessary to thoroughly wash off the sweat on the hands and apply high-quality mineral oil before operation. Especially during the rainy season and summer, attention should be paid to rust prevention.

Keep the environment clean

Keep the linear guide and its surrounding environment clean. Even tiny dust that cannot be seen by the naked eye entering the guide will increase its wear, vibration, and noise.

Installation should be done carefully and meticulously

Linear guides should be carefully installed and used, and strong stamping is not allowed. It is not allowed to directly strike the guide rail with a hammer, and pressure transmission through rolling elements is not allowed.

The installation tool should be suitable

Use appropriate and accurate installation tools for linear guides, and try to use specialized tools as much as possible, avoiding the use of fabrics and short fibers.

Clean the guide rail:

As one of the core components of the equipment, the guide rail and linear axis play a role in guiding and supporting. In order to ensure high machining accuracy of the machine, it is required that its guide rails and straight lines have high guiding accuracy and good motion stability. During the operation of the equipment, a large amount of corrosive dust and smoke will be generated during the processing of the workpiece. These smoke and dust will accumulate on the surface of the guide rail and linear axis for a long time, which has a great impact on the machining accuracy of the equipment and will form corrosion points on the surface of the guide rail and linear axis, shortening the service life of the equipment. In order to ensure the normal and stable operation of the machine and the processing quality of the product, it is necessary to carefully carry out daily maintenance of the guide rails and linear axes. Attention: Please prepare dry cotton cloth and lubricating oil for cleaning the guide rail. The guide rails of the engraving machine are divided into linear guide rails and roller guide rails. Cleaning of linear guide: First, move the laser head to the far right (or left), find the linear guide, wipe it with a dry cotton cloth until it is shiny and dust-free, and then add a little lubricating oil (sewing machine oil can be used, do not use machine oil). Slowly push the laser head left and right a few times to evenly distribute the lubricating oil. Cleaning of roller guide rail: Move the crossbeam to the inside, open the end covers on both sides of the machine, find the guide rail, use a dry cotton cloth to wipe clean the contact area between the two side guides and the roller, and then move the crossbeam to clean the remaining area.